The surface transportation sector contributes to emissions of both long‐lived greenhouse gases and short‐lived climate forcers, including aerosols and precursors of ozone. In recent years, India has undertaken several initiatives to accelerate the country’s decarbonization of transportation and adoption of electric mobility.

The air in our cities is polluted and the Indian government has taken timely steps to put brakes on this menace. Schemes like FAME (Faster Adoption and Manufacturing of Hybrid and EV) and PLI (Production-linked Incentive) are helping India develop an ecosystem for electric vehicles (EVs). The government is incentivizing the ownership of EVs and has formulated policies which stipulate that only EVs will be registered after 2025 and will phase out all fossil fuel vehicles from our cities by 2030.

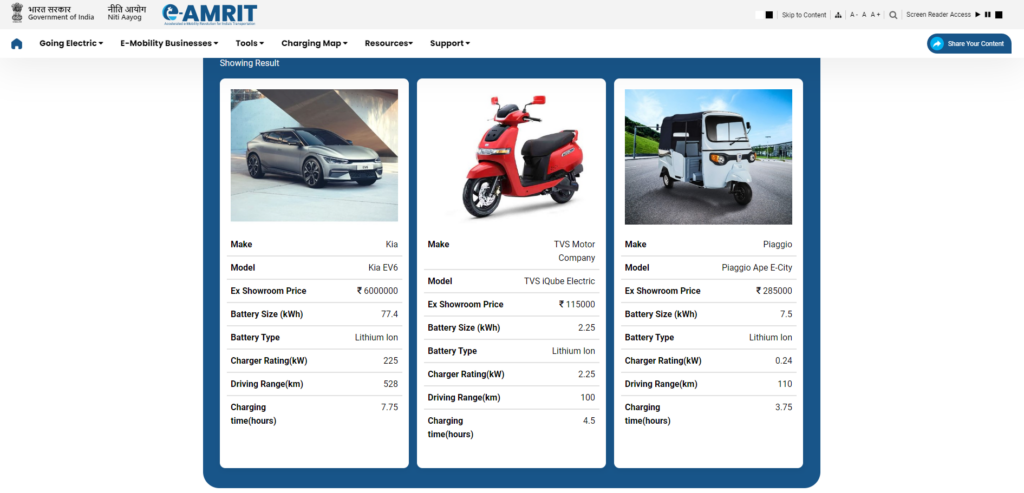

Indian government launched an e-AMRIT portal, which provides insights on the key initiatives of central and state Governments by which users can assess the benefits of electric vehicles with uniquely designed tools on the portal to calculate the savings with electric vehicles compared to petrol/ diesel vehicles, information about the Indian electric vehicle market and other points.

BIS, ARAI, CEA and other agencies helped define standards for EVs in India. Companies like Tata Motors, TVS Motors, Mahindra & Mahindra, OLA Electric, and others, have established production lines that roll out electric vehicles at a furious pace. Kia Motors came up with a vehicle named Kia EV6 that can travel 520 km on a full charge. On the other hand, Kinetic Green Zing comes with a 1.8 kWh battery which takes 4h to charge and has a driving range of 100 km.

The Indian government is also strengthening the ecosystem by encouraging entrepreneurs to explore business opportunities in various sectors like Micro-mobility, ride-sharing, etc. It would also do well to strengthen the battery supply chain. We all know that the energy of batteries is normally measured in kWh. Close to 850 grams of LCE or Lithium Carbonate Equivalent (150 grams of Lithium metal) is needed in the battery for every kWh of power.

Approximately 3 crore registered cars or passenger vehicles ply on our nation’s roads. Each car will need about 35 kWh of battery, once electrified. Therefore, India will need to shore up an estimated 150,000 Tons of Lithium metal only to provide the first set of batteries to the newly assembled electric passenger cars, excluding electric scooters, electric rickshaws, electric trucks and the like.

Because this Lithium is currently being imported, we will need to be very judicious in our designs. Some cars like Hyundai Kona require 39 kWh to move 450 km while others like Kia EV6 need 77.4 kWh battery to drive 520 km. When cement availability was low in our country, the government regulated building designs to conserve cement. Our policy planners would do well to consider a similar regulation on Electric vehicles’ batteries, drive train systems and other sub-systems; that have a direct impact on the amount of lithium metal getting used per ton-km of movement.

China processes 60% of all the Lithium mined in the world. But, that’s not all. China also controls the processing of 100% of all Graphite, 65% of all Nickel, 93% of Manganese, and 82% of Cobalt. Moreover, 73% of all Lithium-ion batteries are made in China.

If proper planning isn’t done, India would become dependent upon China for moving people and cargo on our streets. We would also run the risk of enriching China in our zeal to become carbon neutral.

As things stand, there are two possibilities. Purely because of the logistical challenges in procuring reserves from South America, the first option the Indian government could exercise is to team up with African countries rich in Lithium reserves. Zimbabwe, Mali, the Democratic Republic of Congo (DRC), Ghana and Namibia have about 4.3 Mn tons of Lithium deposits between themselves. Over 70% of the world’s known Cobalt reserves are in DRC and 80% of the world’s manganese deposits are in the Kalahari Desert region abutting South Africa.

Logistically, teaming up with South Africa, Namibia & Zimbabwe would be easier. The Namibian government was generous enough to give us Cheetahs to experiment with a re-introduction plan. South Africa and India have historically been close.

Since the days of the Munhumutapa Kings in the 14th century, Zimbabwe and India have had good relations. However, China is winning friends in this region with eyes on their natural wealth. China’s exposure in Namibia is close to 2% of Namibian GDP, China is one of South Africa’s leading trade partners, providing broadcasting equipment worth USD 10 Billion and purchasing diamonds and Manganese ores worth USD 4 billion. Zimbabwe’s foreign debt is about USD 14 Billion, while its Lithium reserves are estimated to be close to USD 14 Billion. According to Zimbabwean Government, the illegal trade of lithium has cost them USD 12 billion in losses and many multinational companies process the lithium mined from Zimbabwe and re-sell the same in the form of expensive batteries and other gadgets. Therefore, the Zimbabwean government has banned the export of raw lithium ore and wants to process Lithium on its soil.

India must quickly deploy and execute a well-developed strategy to ensure a win-win for both Africa and India. India is in the process of helping the government of Mozambique improve the quality of power supply, Indian government is helping CFM, the national rail operator of Mozambique, acquire high-quality rolling stock. By developing a cape-specific project linking Namibia, Zimbabwe, South Africa and Mozambique, India would not only boost the regional economy, and help local governments lift thousands out of poverty but will also earn a lot of goodwill and secure its long-term strategic interests.

India can also improve the circularity of its e-waste supply chain. Becoming the world’s e-waste recycler will not only generate employment but will also give us access to rare-earth oxides. It is estimated that the management of domestically generated e-waste, amounting to 2 million tons every year, has an employment potential of 4.5 lakh jobs by 2025. This will also help us reduce the leaching of harmful chemicals into our soils, reduce the need for us to mine rare earth minerals and possibly help us meet our COP27 objectives. Until a few years ago, ionic-liquid extraction technology, membrane technology, cellulose-based adsorption process and other advanced technologies were available only to researchers. Nowadays, many of these technologies are commercially available. When the scale is added to the equation, viability issues vanish and the entire endeavour becomes economical. These advanced technologies can be used to extract rare-earth oxides from e-waste. And, with a little bit of ingenuity, they can also be used to extract valuable minerals from mine tailings and other previously ignored waste chains.

Fortunately, India is endowed with a long coastline and rich iron-ore wealth. Many of these techniques, can come in handy to extract rare-earth oxides and minerals from sources lying in plain eyesight and help India strengthen its strategic reserves. Therefore, the second task at hand is to invest in the acquisition of such technologies while strengthening the circularity e-waste supply chain.

(The author is an entrepreneur and writes on technology and business. Opinions expressed are the author’s own)